Case Study

Comfortably moving trolleys weighing over 500kg in a 'just-in-time' inventory system.

With only a small investment, this company has greatly reduced the physical burden on workers!

TERAL INC.

Logistics Section, Production Department

Kai-san and Mizoue-san

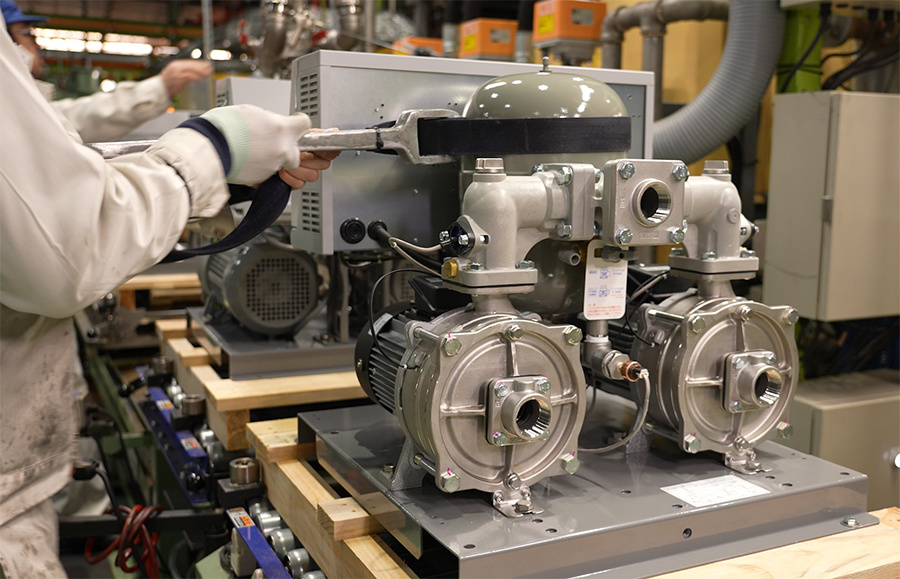

TERAL INC. develops and manufactures a variety of products that control the flow of air and water, such as pumps and fans. The company has installed the Assist Wheel Drive system at their headquarters.

We spoke with Kai-san and Mizoue-san from the company's Logistics Section (Production Department) about the issues they faced at the time, why the system was introduced, and the results.

(the following video has English subtitles:)

"Before, heavy trolleys couldn't immediately be stopped, and there was a risk of danger."

The Logistics Section brought in the Assist Wheel Drive system as a safety measure, to reduce the physical burden on on-site workers.

Kai-san (Logistics Section Manager) commented on Assist Wheel Drive's effectiveness at both reducing the physical load and improving efficiency: "Compared to before [it] was introduced, workers experience less fatigue, and we can transport items much more effectively."

He also discussed safety: "Before, heavy trolleys couldn't immediately be stopped, and there was a risk of danger. Now, they can be stopped with a simple action that's always on hand. From a safety perspective, we are very satisfied with the system."

The company's pumps are made primarily using metal components. The 'standard type' parts that are shipped in large quantities weigh roughly 50kg each. If 8 of them are carried on 1 trolley, the total load weight is close to 400kg.

In addition, the parts are positioned to match the height of the workbench, so that there is no need to raise and lower them at the assembly site. This positioning means that the trolley must be stable.

The company makes its own trolleys for transportation within the factory. They are made with solid metal, and are also heavy.

At work sites that use the 'just-in-time' inventory system, numerous trolleys and forklifts come and go all day.

Trolleys over 500kg (including the weight of the trolley itself) sometimes need to be stopped at intersections and turned 90 degrees (or 180 degrees at line-side). Before Assist Wheel Drive was introduced, workers had to lean in diagonally with their hips to set off, take a firm stance and lean backwards to stop, and pivot on 1 foot while turning. All of these actions were physically demanding for workers.

Furthermore, as Kai-san recalls: "(under the 'just-in-time' system) We must prepare the parts needed as and when they are needed and in the quantities needed, all of which puts strain on workers."

Following Assist Wheel Drive's introduction, in Kai-san's own words, not only has worker fatigue dropped, but the company is also satisfied with increases in work efficiency and safety at the factory.

As for ease of operation, Mizoue-san (Logistics Section Group Leader), who demonstrated how Assist Wheel Drive is used at the factory, commented:

"You quickly get used to operating the lever. Just pull it back lightly to stop. It doesn't act like an emergency brake, and there's no need to use force - it stops without travelling too far."

An existing company-built trolley can be converted into an electric power-assisted trolley in half a day.

With only a small investment, this company quickly realized the benefits!

As previously mentioned, the trolleys used at TERAL's work sites are heavy models made in house.

Reflecting on when Assist Wheel Drive was introduced, Mizoue-san said: "There are surprisingly few electric power-assisted trolleys that can be created by retrofitting existing company-made trolleys. When Assist Wheel Drive was presented to us, we thought 'this might work'."

From there, we carried out an on-site demo, and showed that Assist Wheel Drive can reduce the physical burden on workers. TERAL started by fitting Assist Wheel Drive on 1 trolley, but quickly moved to install the system on every trolley.

"With the first unit, we had to try a few times to get the installation position right. After that, it took only half a day to a day to introduce the system on the factory floor.

Assist Wheel Drive comes as a package with all the parts needed: the battery, the controller, the suspension, etc. That makes it easier to retrofit existing trolleys and start using them.

With only a small investment, we quickly realized the benefits of Assist Wheel Drive, and on-site workers are very pleased with the system."

Aiming to create a more comfortable work environment for employees

As Japan's working population declines, it's said that businesses (regardless of industry) will need to create an environment suitable for a diverse workforce. Manufacturing sites in particular are still associated with the 3Ds (Dirty, Dangerous, and Demeaning).

Kai-san: "The managing director tells us 'You must not carry anything heavier than I can carry' (15kg)."

On hearing this, we were curious about the assembly site. It doesn't have the typical image of an area used for handling heavy objects.

Pallets move through the assembly process on roller conveyors. At each stage, a rotating table and lifter are used to hold the pallet in position for simpler working. The ability to assemble parts without changing position or posture reduces the physical burden on workers, and helps to prevent accidents.

Referring to the Assist Wheel Drive system being installed on every trolley, Kai-san commented: "Up to now, only men were able to move the trolleys because it was heavy work. With Assist Wheel Drive, we found that anyone could control a trolley."

"Depending on the work environment, people tend to avoid 3Ds work and other difficult tasks. We believe that using trolleys fitted with Assist Wheel Drive is a highly effective way to reduce that burden and create a more comfortable work environment for employees."

Company Overview: TERAL INC.

TERAL INC. was founded in 1918. The company has been developing and manufacturing a variety of products that control the flow of air and water, such as pumps and fans, for over 100 years.

Production Department, Logistics Section

This team purchases, receives, and inspects products delivered by suppliers. They send items to each production line (line-side logistics) to help achieve the 'just-in-time' inventory system, and handle internal logistics such as shipping products and components within the company.

Assist Wheel Drive (AWD)

AWD can be quickly installed (in appx. 10 minutes by 2 people), and provides immediate electric power assistance to the trolleys you already use. It adds supporting force to push the trolley when transporting heavy objects.

The controller is mounted on the trolley handle for easy access. The forward/reverse speed can be adjusted to suit the operating environment.

The Assist Wheel Drive 150 series can transport a maximum load of 1,000kg (1 ton), and the Assist Wheel Drive 160 series can transport up to 750kg.

© IDEC Corporation. All rights reserved.