6 reasons to choose a unibody Emergency Stop

Emergency-Stop (E-Stop) switches are critical safety devices used to halt machinery and equipment in emergency situations, preventing injury or damage. Among the various designs available, unibody E-Stop switches have gained prominence in modern applications due to their robust construction, reliability, and ease of installation.

Why should you consider using unibody E-Stop switches?

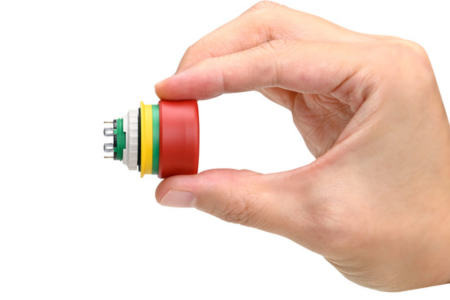

Robust construction

Unibody E-Stop switches are designed with a single, integrated unit construction, which eliminates the need for multiple components or assemblies. This design significantly reduces the risk of mechanical failure, loose connections, or misalignment, ensuring consistent performance over time.

Environmental resistance

The solid construction also makes these switches highly resistant to common environmental factors such as dust, moisture, and vibration. As a result, they are well-suited for demanding industrial settings where reliability and durability are critical.

Easier setup and maintenance

The unibody design simplifies the installation process by reducing the number of parts that need to be assembled or aligned. This not only speeds up installation but also minimizes the risk of errors during setup. Maintenance is also easier with unibody E-Stop switches, as the integrated design reduces the likelihood of wear and tear on individual components. This leads to lower maintenance costs and less downtime, making them a practical choice for industrial applications.

Space-savings

With a compact design, less space is required compared to modular designs. This makes them ideal for applications where control panel space is limited or where a streamlined design is preferred. Their small footprint allows for efficient use of space without compromising on functionality or safety.

International standard compliance

Safety compliance is a must, and unibody E-Stop switches are designed to meet stringent international safety standards, such as ISO 13850 and IEC 60204-1. Their robust construction ensures reliable operation in emergencies, helping organizations comply with regulatory requirements. Additionally, the integrated design reduces the risk of tampering or accidental disassembly, further enhancing safety. This makes them a reliable choice for ensuring compliance and protecting personnel and equipment.

Aesthetics

With sleek, modern designs, they integrate well with contemporary machinery and control panels. This not only improves the overall aesthetics of the equipment but also maintains high functionality. The combination of form and function makes them a preferred choice for modern industrial environments.

What limitations for unibody E-Stop switches?

A unibody E-stop switch, while offering the advantage of a compact design, does come with certain limitations due to its size. Typically, it supports 2NC (normally closed) contact configuration, but with the IDEC XA1E-BV3SG, the option is extended to include either 1NO (normally open) contact or illumination (red or color changing), something unique in the market. However, this configuration may not meet the requirements of all applications, particularly those needing more complex contact arrangements.

The trade-off lies in balancing the need for minimal space behind the panel for mounting and termination with the functional demands of the application. This challenge is inherent in all use cases, as the compact nature of unibody E-stops restricts the number of components and features that can be integrated. While the design excels in space efficiency and simplicity, it may fall short in scenarios requiring more advanced or customizable configurations.

Unibody E-Stop switches address the needs of modern industrial applications by providing a durable, low-maintenance solution that ensures reliable emergency shutdowns. Their compact design and ease of installation make them well-suited for use in advanced manufacturing, robotics, and automated systems, where space and performance are critical. While they may have some limitations, their benefits often outweigh the drawbacks, making them a preferred choice for many modern applications. Their ability to combine durability, safety, and efficiency ensures they remain a key component in industrial safety systems.

Explore the Unibody Emergency-Stops from IDEC