Push-in vs spring clamp terminals: faster installation and safer connections for critical stops

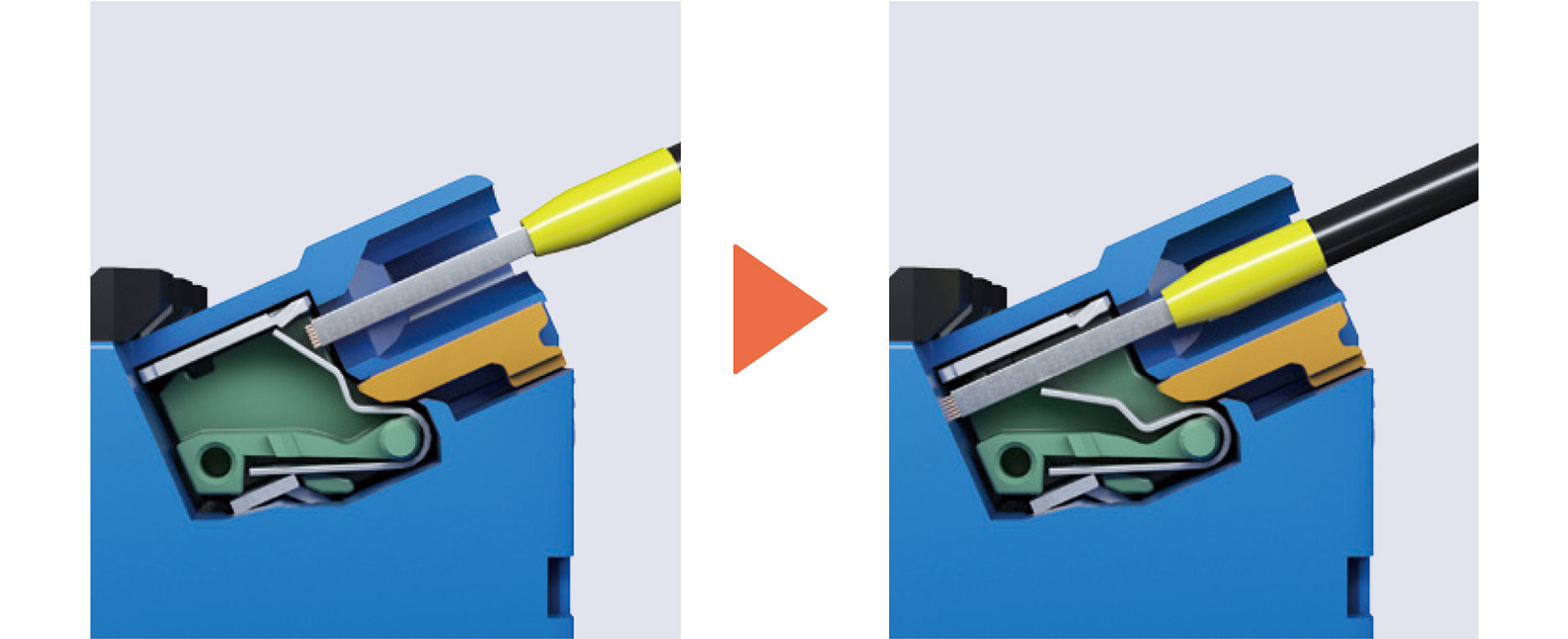

Push-in terminals: How do they work?

Push-in terminals are a type of electrical connector that allows for quick and secure wire connections without the need for screws or tools. Wires are simply inserted into the terminal, where a spring-loaded mechanism holds them firmly in place. This design simplifies the wiring process and ensures a reliable electrical connection.

When connecting

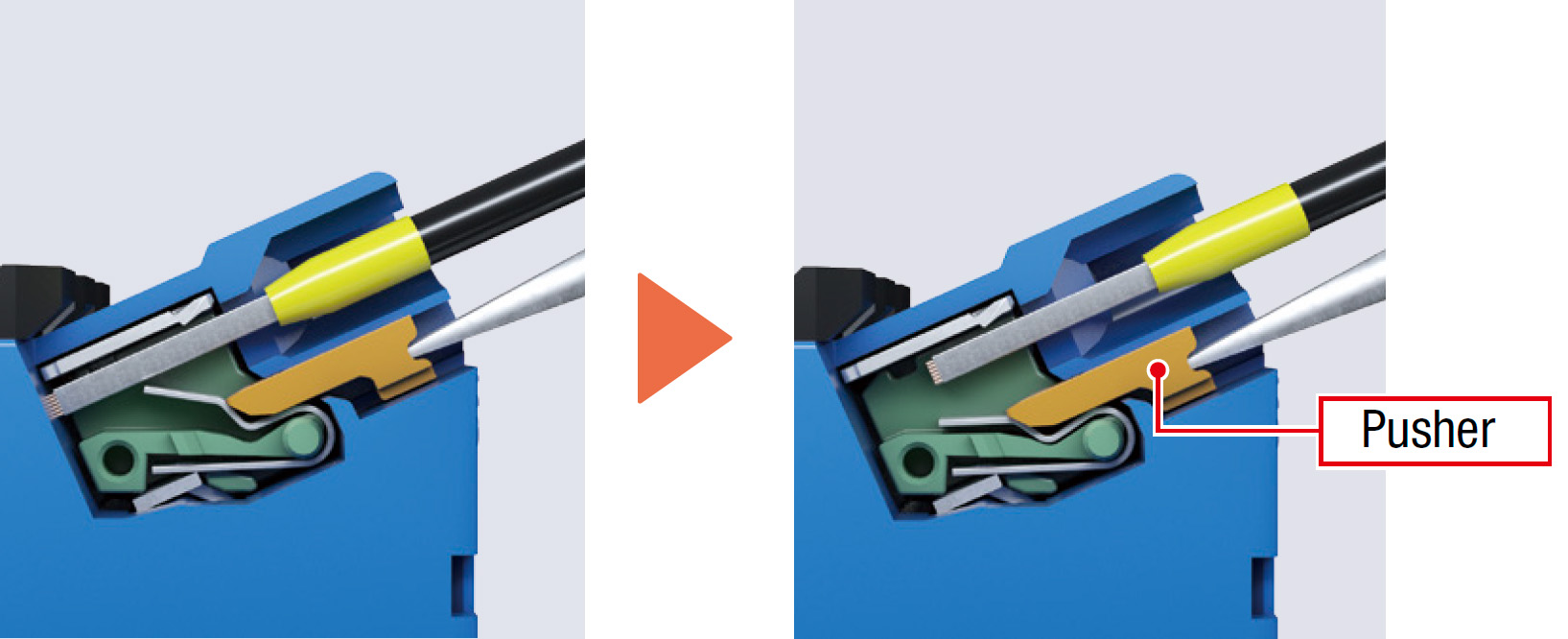

When removing

What benefits can you get from push-in terminals?

- Tool-free installation: wires can be connected quickly and easily without the need for screwdrivers or other tools.

- Secure connection: a spring-loaded mechanism ensures a firm and reliable grip on the wire.

- Reusability: wires can be easily removed and reinserted, facilitating maintenance and modifications.

E-Stop switches with push-in terminals: what advantages?

Push-in terminals offer significant advantages in the installation, reliability, and maintenance of E-stop switches. Their tool-free design enables quick and easy connections, drastically reducing installation time and labor costs, which is especially beneficial in large-scale setups requiring multiple E-Stops. The spring-loaded mechanism ensures a secure and consistent connection, minimizing the risk of loose wires or electrical faults—a critical feature in safety applications where E-stop functionality is essential to prevent accidents and equipment damage. Additionally, push-in terminals simplify maintenance and modifications, as wires can be easily disconnected and reconnected without tools, reducing downtime in dynamic industrial environments where equipment configurations frequently change.

E-Stop switches with push-in terminals: what applications?

The intuitive design of push-in terminals reduces the likelihood of wiring errors during installation, which is crucial in safety-critical systems where incorrect wiring could compromise functionality. Furthermore, push-in terminals provide a vibration-resistant connection, ensuring reliable operation in harsh environments with mechanical stress or shocks. This is particularly important not only during machine operation but also during transport, where vibrations can risk damaging electrical connections. These features make push-in terminals an ideal solution for both industrial applications and pre-transported products, ensuring reliability and efficiency.

Push-in versus spring clamp terminals: what difference?

Spring clamp terminals are similar to push-in terminals, but have key differences, particularly around the design for securing wires. In addition, they differ primarily in their installation time and ease of use.

Push-in terminals are faster to install, as wires can be inserted directly without additional steps. Spring clamp terminals, on the other hand, require manual operation of a lever or button to secure the wire, which takes slightly more time.

Push-in terminals offer significant benefits for E-stop switches, including simplified installation, enhanced reliability, improved maintenance, reduced wiring errors, and vibration resistance. These advantages make push-in terminals an ideal choice for a wide range of industrial applications, from industrial machinery to process control systems.

If you’d like to take advantage of push-in terminals, take a look at our YW series:

▶YW Series